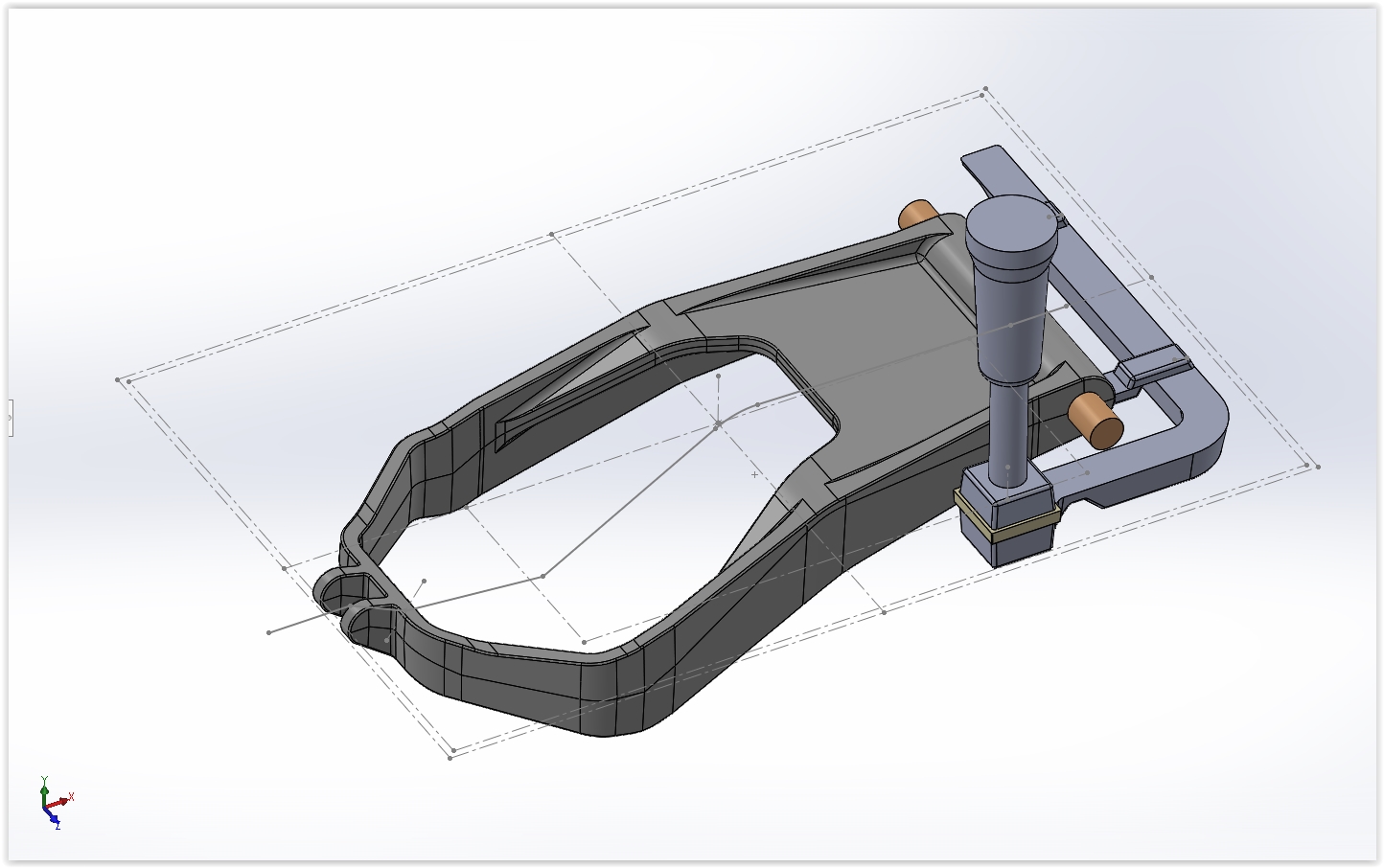

Environment includes noise, dirt, sand, dust, molten metal, sparks, and inclement weather. Anyone in this position must be able to move freely around a variety of industrial equipment. Will routinely climb, bend, walk, sit and reach throughout the day. Work is performed in a heavy industrial environment as well as office space. Foundry and office conditions are equally likely. Work conditions vary based on assigned tasks. Familiarity with Steel foundries and green sand systems is highly desired.Bachelor's Degree in Manufacturing Technology, Material Science, Mechanical Engineering or Metallurgical Engineering, or demonstrated equivalent.Familiarity with Continuous Improvement in team-oriented work environment.Make decisions in a constantly changing environment, and know when to move the decision elsewhere in order to accomplish assigned work.Good organizational skills, self-managed, detail-focused.Knowledge of mechanical, metallurgical, and engineering terminology and processes.Knowledge of laboratory tests chemistry and gas analysis.Knowledge of the different sands and sand processes used in steel foundries.Desire to learn continually and stay abreast of new technology.Computer proficiency in MS Office and AutoCAD/SolidWorks.Understanding of Solidworks and their application (i.e., flow, stress analyses) is helpful.Ability to produce written reports suitable to describe problems and propose actions.Knowledge of drawings and blueprints for the purpose of developing production methods.

Casting engineer magmasoft software#

Ensure each process worked-with and developed is conducted in safest possible way.They will also work with the Melting Manager to improve the melting process. This role will work with Molding personnel, Sand System Manager, Foundry Manager and Product Engineers to identify improved casting outcomes through changes in rigging, metallurgy sand specifications, etc. This role will conduct material tests to control and optimize manufacturing operations at the foundry, collect and enters process control data and conduct root cause analysis on casting defects. This position is responsible for monitoring, controlling and improving production processes to improve casting quality. This administrative and technical position resides in the Foundry Operations and plays an integral role in maintaining and advancing the technical capabilities of Columbia Steel.

0 kommentar(er)

0 kommentar(er)